Not for the faint hearted

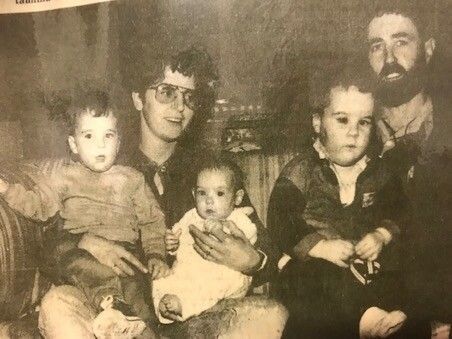

Timothy, Philippa, Gerardine and Chris Redwood on the Forsyth wharf.

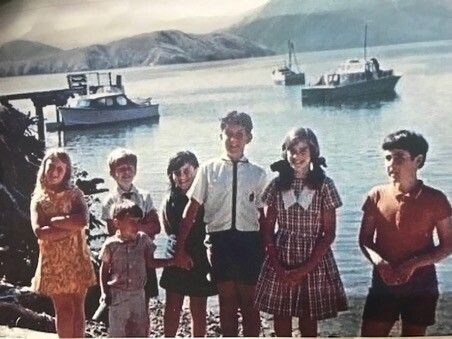

Homewood Hall hosted a school day out in summer 1968. From left Glenda Robb, Richard, Rodney and Jane Paterson, Chris Jones, Susan Paterson and Chris Redwood.

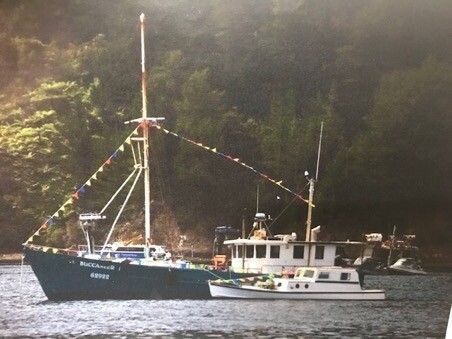

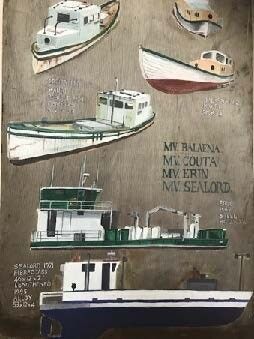

Redwood vessels Buccaneer and Balaena at Hopai Sports 100 years. Built 1912, Balena chased whales to 1925 and was Dr Vic Jacobson's first whale chaser.

Vincent, Trish, Zoe, Patrick and Chris.

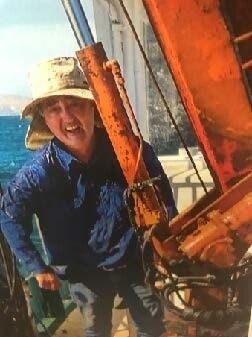

Chris Redwood soaking wet after the splash from dropping a 100kg weight over the side.

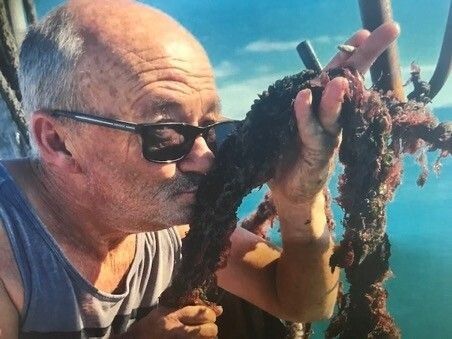

Kiss that spat – marine engineer Andy Robertson at Clifford Bay.

Chris and Trish Redwood of pioneering vacuum-packed mussel producers Omega Seafood might be described as salt of the earth people, or more accurately, salt of the sea.

Chris grew up on wind-lashed Forysth Island in outer Pelorus Sound. His father Pem (Pembroke Henry Redwood) instilled a hard work ethic in his family, which was fortunate because after 40+years of mussel-farming and production, Chris is still hard at it along with Trish.

There are wider family values at play, as reflected in how the company’s 20 staff, including some long-servers, who are thanked after each shift at the plant in the Cloudy Bay business park near Blenheim.

The family legacy is reflected in Omega’s company structure named PHR Processing Ltd and PH Redwood farms. Pem and his wife Gerardine farmed sheep at Forsyth but even before Chris went off to do a diploma in agriculture at Lincoln in the late 1970s, he had seen the future was not in farming the rugged 750 hectares.

“It was nearly crofting. Granny helped with the school fees to keep us going. You had to diversify and the only thing at the time was mussels.’

Chris was the driving force in the family leasing line space from Davy Jones at nearby Whakatahuri Bay before buying a licence from Francis Wells. The Redwoods supplied NZ Marine Foods with mussels for processing and the fresh mussel trade.

Chris met Trish in May 1985 and their first date was at a hockey cabaret in Blenheim (Trish was a Marlborough rep.) They married in September that year and she moved to live at Forsyth. The following year sheep farming became even more marginal with Rogernomics wiping guaranteed minimum pricing.

To help supplement the family’s income, Chris took on managing the Titirangi Farm Park (1986-92) for what would become DOC, as well as leasing half of neighbouring Pohuenui island. He also developed more farms in and around Forsyth Island which would eventually prove their value as sources of spat and also supply of mussels when algal blooms affected inner Sounds farms.

But in earlier years, being five hours steaming time from Havelock didn’t make the family’s mussels attractive to companies which could do round trips to other farms in the same time.

So, Chris began crossing Cook Strait in Sealord, a 44ft former fishing boat, to land fresh mussels directly to clients at Paremata north of Porirua.

“The first trip we got a cheque and it bounced. It was to be a good lesson in fiscal management.”

They framed the cheque. “You have to keep positive.” Ironically, it was another debt that turned them towards developing into vacuum packed processing.

Marlborough mussel industry pioneer John Turner owed Chris $40K for seeding and harvesting work he’d done. John couldn’t pay but offered them some processing

and vacuum-pack equipment. “I should have, in retrospect, have put the gear on the truck and taken it to the dump,” says Chris. Trish says the change from grower to

processor is immensely challenging.

"It's just a massive minefield.”

Meanwhile, Forsyth Island was proving its own challenge, not least because the Redwoods had started a family with twins Patrick and Vincent, born 1988, being the first of six children who needed to go to school.

Pem and Gerardine had moved to Blenheim in 1991 and in 1994, Chris and Trish sold Forsyth Island to German investor, Dr Farhad Vladi, who now lists it among a series of exclusive islands he rents out around the world!

The Redwoods bought 180ha at Seaview in the Awatere Valley, leasing 80ha to what is now Pernot Ricard. They moved the former Catholic presbytery to the site and refurbished it as their family home. Some of the land is grazed by both sheep and horses which have become a family passion.

Still living near the coast, the couple began eyeing up the waters off the Awatere coastline. It was the start of a 20-year battle to establish a huge greenshell mussel farm at Clifford Bay.

“It’s not for the faint hearted,” says Chris. Some 424ha was eventually allocated though only 2ha has been developed as a spat farm in front of Yealands vineyards near Seddon. The Redwoods remain shareholders with others including Ngai Tahu. Chris says it’s been challenging to get equipment that works in an open ocean environment but says it’s now producing excellent spat.

With farming operations managed by staff, Chris and Trish put their energies into processing, leasing the factory in 2004. Initially they processed fresh mussels before the trial and error of vacuum packs. The Omega Seafood brand packages freshly cooked whole greenshell mussels in 500g and 1kg packs.

Vinny (Paddy’s twin) left his job at a local accountancy firm to help manage all the administration and compliance that processing entails.

“We could not have done it without him,” says Trish. Her sister Jo O’Connell went cold-calling restaurants to sell the packs.

“These didn’t exist before. The idea of making mussels clean and convenient worked - eventually.”

New food safety rules helped.

The company now also markets clams sourced from Golden Bay or Dunedin’s Blueskin Bay.

Meanwhile Chris was struggling with a lung auto immune disease which eventually saw him in August 2020 get one of the 15-30 lung transplants done each year in NZ

from donors who have passed.

“It’s somebody else’s tragedy and our miracle.”

By 2020, Omega Seafood was starting to hit its stride, with 85% of its 2000 tonne production exported mostly to overseas restaurants – including Australia, China, Asia, the Middle East and Denmark.

Then Covid-19 hit. “We went from a full order book to nothing overnight,”

Trish recalls.

Things are now recovering with 20+staff and plans to lift production to 3,000

tonnes.

Son Patrick now manages the factory and daughter Lizzie does the marketing and other family have been involved.

“We chose if we can, to only work with family-owned and run companies,” says Trish, who remains active on Omega’s board. “There’s continuity and their values don’t change overnight.”

You see those values at their factory. Cairo Ngawhare, who’s just been promoted to supervisor after 8-9 years at Omega, says it’s an awesome place to work. “It’s like being in a family.”

One where hard work is in the genes along with salt.

Contact us

Phone: 03 578 5044

Physical address:

Ground Floor - WK Building

2 Alfred Street

Blenheim

Postal address:

PO Box 86

Blenheim 7201